Gas Fills

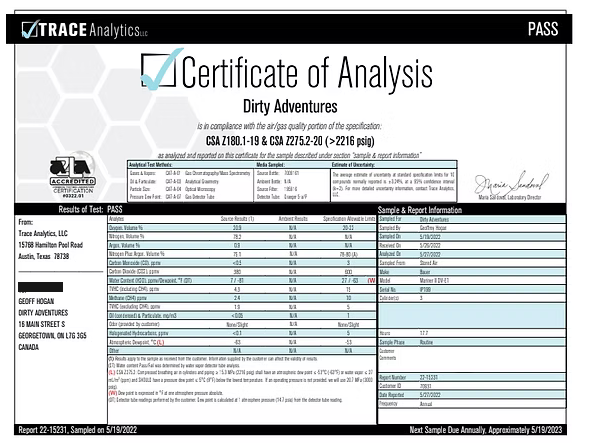

At Dirty Adventures Scuba, we strongly believe in safety, and that starts with the gas that we are breathing underwater while scuba diving. All of our air is filtered, dried, and oxygen compatible. We conduct regular air tests to meet CSA Z180, CSA Z275, and exceed CGA Grade E air purity testing requirements.

For divers with steel tanks and twinsets, we offer the ability to fill cylinders in your vehicle – just ask!

We offer air fills from our high pressure cascade system, with banks equaling 10,000 cubic ft of air. That is the same volume of air as two semi-trailer trucks! For you, this allows us to fill your cylinders without running the compressor and with minimal turnaround time. If you’re interested, please see “About Our Compressor and Fill Station” below for further details.

We also currently offer nitrox fills up to 40% using partial pressure blending. Blends above 40% (e.g. 50/50) can be done upon request with appropriate certification. A special inspection of your cylinder may be required for nitrox fills; please contact us for details.

Please note, we do not overfill cylinders. All cylinders will be filled to their working pressure as specified on their markings (temperature adjusted). We can fill up to 4500psi, but this may require leaving cylinders with us. Fills for up to 3500psi can usually be filled immediately.

Argon fills for drysuit offboard inflation is subject to availability — please contact us to inquire.

We now offer Trimix! Please call in advance should you like a Trimix fill.

Analysis Report, May 2022

Fill Station Policy

You must present proof that you are a certified diver in order to fill a SCUBA cylinder. Additional certifications are required for nitrox and/or oxygen fills (subject to availability).

By law, Transport Canada (TC) requires hydrostatic testing every five years, and the current scuba industry best practice is to require visual inspections every year. We will not fill any cylinder after the last day of the month in which the visual inspection or hydrostatic test has expired. We can arrange hydrostatic testing and visual inspection of your cylinder should you require one — please contact us for details.

Visual inspection stickers must be readable and identify the store or inspector that conducted the inspection. Generic visual inspection stickers will NOT be accepted. Cylinders for paintball use will be filled only if they are marked with a “Paintball Use Only” sticker.

Regarding 6351 alloy aluminum (aka “old” or “bad” aluminum)

We will not fill 6351 alloy alumnium scuba cylinders (some alumnium cylinders manufactured before 1990). For more information, please read: https://dan.org/alert-diver/article/are-6351-t6-alloy-scuba-cylinders-safe-to-use/

We reserve the right to refuse to fill any cylinder we do not feel comfortable filling, even if it is permitted by TC regulations.

About our compressor and fill station (aka the technical nitty gritty)

We use a Bauer Mariner II 7.5hp 8.4cfm electric-motor compressor that is regularly maintained and upgraded to ensure that you get the best breathing air possible. Air from the compressor passes through a Bauer filter tower (P31) containing desiccant, activated carbon, and catalyst (80114 or 80100). From the compressor, air is monitored for carbon monoxide with a continuous CO alarm and a visual indicator that shows signs of moisture or carbon monoxide. Compressed air then flows to our high pressure cascade system that has 3 banks of 4500psi air (6500cf) and one large bank of 2500psi air (3500cf), totalling 10,000cf.